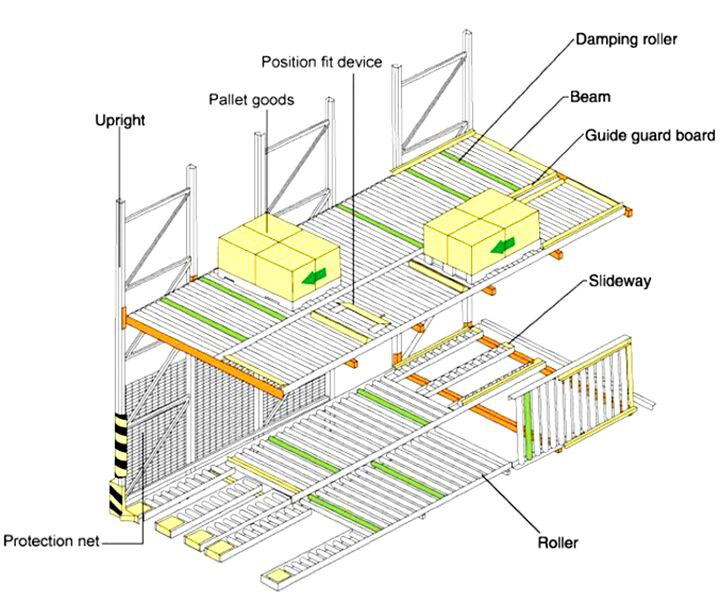

The gravity racking systems use frames and beams as basic structure, and then making the roller system bolted in the beams, which are easy installation and easy adjustment.

The upright frame are clip-in configuration which are easy assembly and disassembly. All material are high quality cold-rolled steel with high strength, good rigidity and load capacity. The ground and frame are connecting by expansion bolts to enhance the stability.

The roller sytem are equipped with seperator divice and damper divice to ensure the pallet sloping safely.

Features & Advantages:

- As boxes are picked from gravity flow racking systems the boxes behind will flow to the front of the system for picking. They flow on roller tracks with plastic wheels

- There are typically 2 roller tracks per lane

- Optional shelf dividers keep boxes straight and prevent them from getting hung up (dividers are not necessary)

- Achieve first in first out (FIFO) inventory control

- Low profile shelves provide a maximum pick window

- Our improved Roller Track holds over 25 LBS per lineal foot and can be designed to hold over 50 LBS. per lineal foot to handle heavy loads and stand up to impact

- Roller tracks are inverted to prevent dust and debris from building up

- No welded parts. No bolts, screws or pins

- Ships flat and compact

Product Specifications:

|

Model |

Length(L) |

Depth(D) |

Height(H) |

No. of tiers |

|

Gravity flow racks |

1000-2500 |

800-2000 |

1800-3000 |

2-6 |

|

Surface Treatment |

Power Coating or baked paint finishing |

|||

|

Remark |

We take any specific orders according to customers’ requirement. |

|||

Packaging & Shipping:

Product pictures