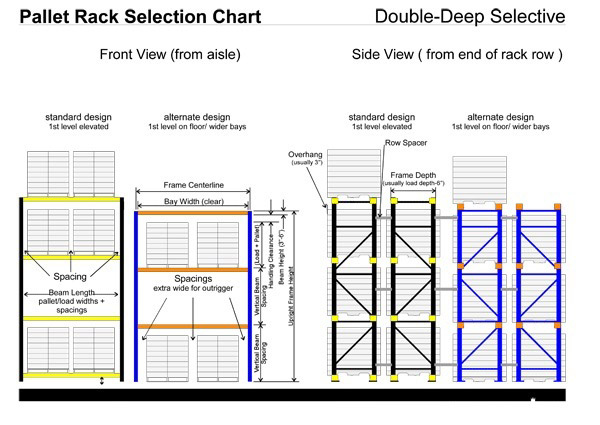

Double deep racking system is similar to selective racking; but pallets are stored two rows deep instead of one row. The most common forklift used for double-deep handing is a reach truck.

Double deep pallet racking stores 2 pallets deep or 4 pallets deep between aisles. It delivers increased storage density when compared to wide aisle and requires specialised fork lift trucks.

Double deep pallet racking simply has one row of standard pallet racking behind another. Using a deep reach lift truck, the operator places the back pallet into the system first, then places another pallet in front of it.

Selectivity is reduced by 30% over standard pallet rack, but 30% more pallets are stored for a given number of aisles. This increases productive use of floor space over a wide aisle system, offering the same sort of utilisation as narrow aisle.

Double deep pallet racking offers low initial cost, high productivity, and good selectivity.

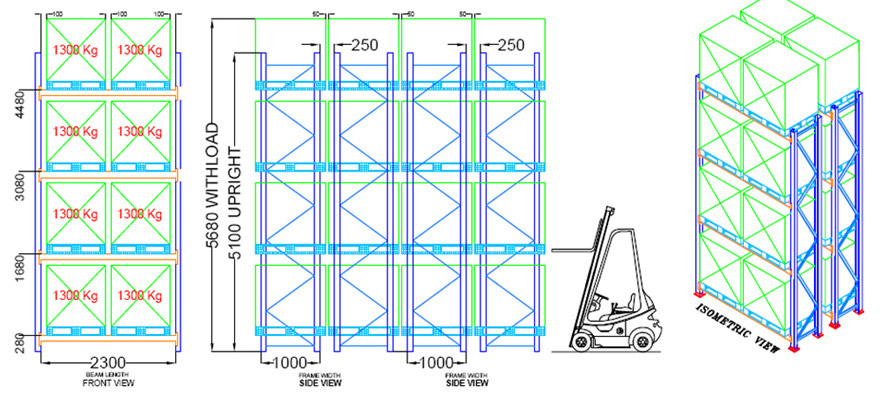

Sample CAD layouts for your reference:

Double deep racking advantages:

- Increased storage density compared to selective racking

- Greater utilisation of available headroom

- Efficient in operation

- Relatively low cost racking system

- Load weights and height limited to forklift capacity

Product Specifications:

|

Load Capacity & Dimension |

Loading capacity: 500-4000kgs UDL/beam level |

|

Main Parts Specs |

Upright section: 80*60*2.0, 90*60*2.0, 90*70*2.0, 100*70*2.0, 120*75*2.0 etc |

|

Surface Finish |

High-quality powder coated/Hot dip galvanised |

|

Color |

RAL 7035, RAL7001, RAL6021, RAL5015, RAL1023, RAL1007, RAL2004, RAL5017 or your requirement |

Product pictures